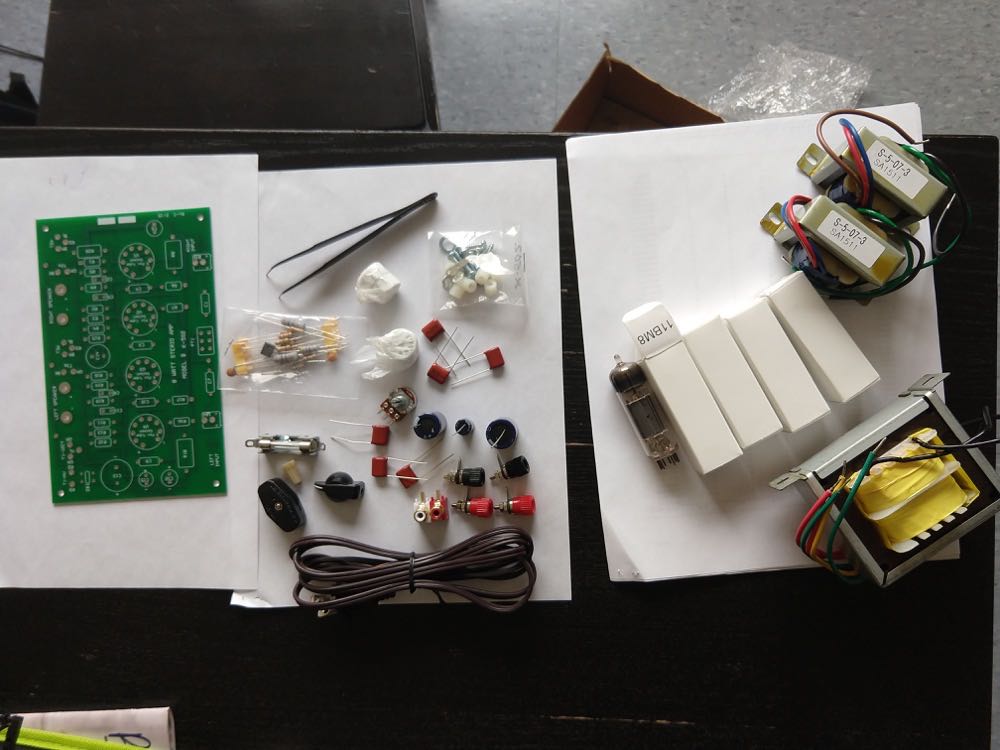

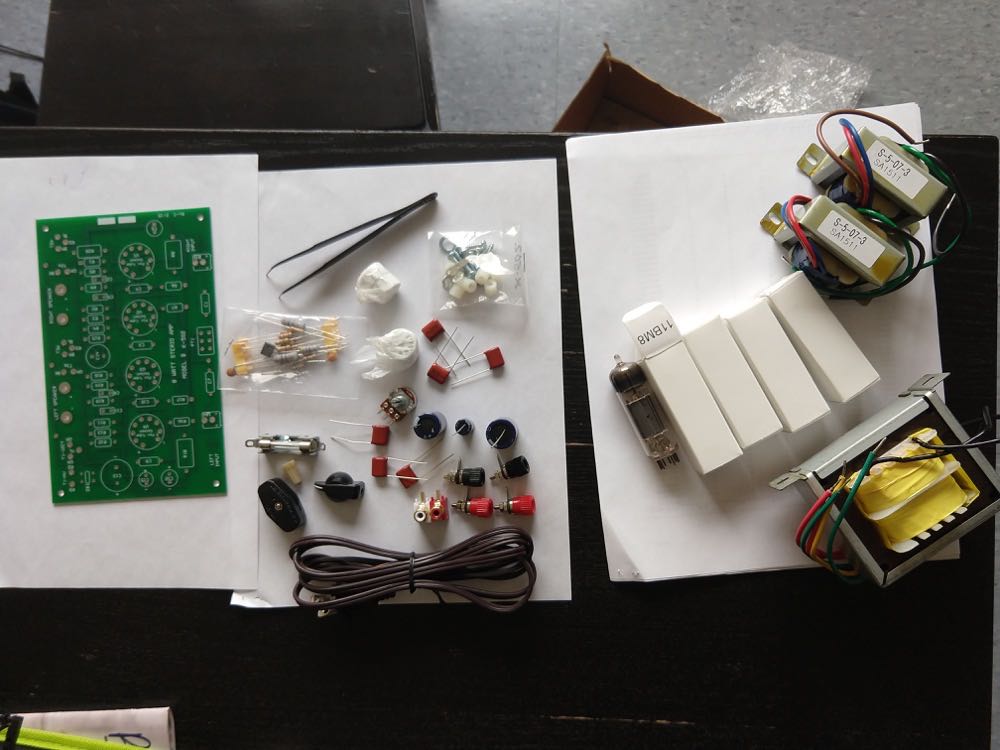

Components of the tube amplifier

Components of the tube amplifierWe have finally approached the wildcard week - the week in which we choose a topic/technique of interest (in the world of a digital fabrication), formulate our own weekly "assignment" and document the progress.

.For the Wildcard week, I have chosen the topic of Sheet metal fabrication, for which I have come up with the following task: "Use CAD tools to design the sheet metal enclosure for your chosen 3D design, cut it, fold it, and describe the major design considerations."

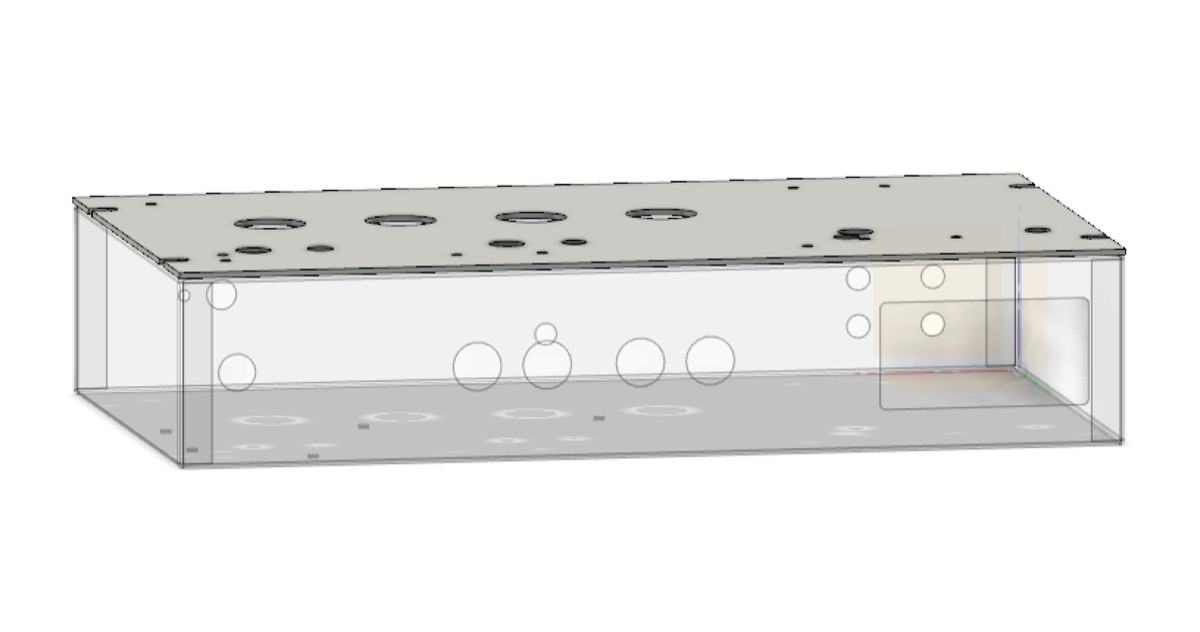

I chose to explore the topic of sheet metal fabrication, as I was in dire need to have proper chassis enclosure for my tube amplifier (Final project). In short, I needed to assemble all my components and place them inside of a steel 10''x6''x2'' box as shown below.

Components of the tube amplifier

Components of the tube amplifier

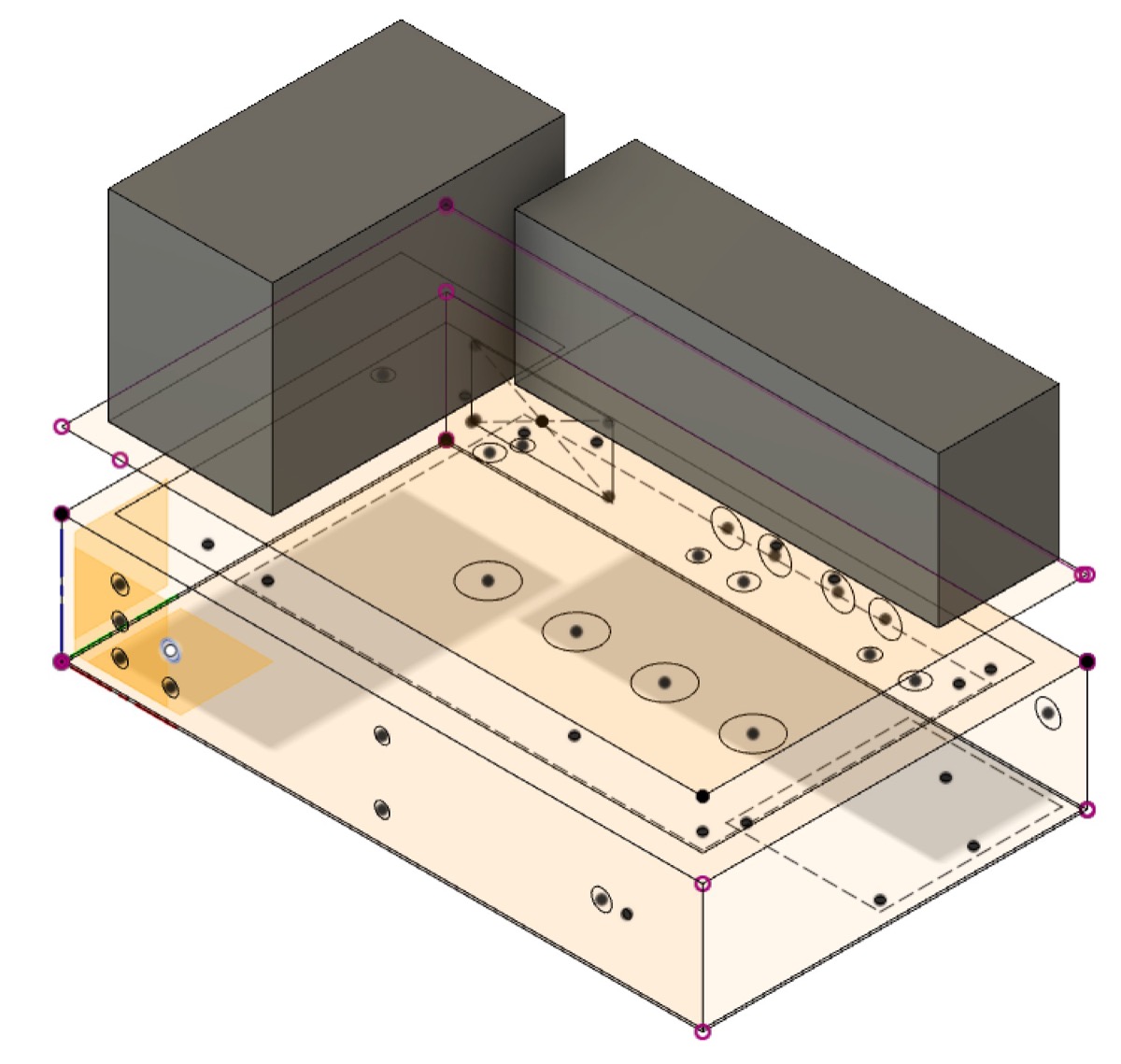

Initial sketches for the amplifier and transformers enclosure

Initial sketches for the amplifier and transformers enclosure

I also decided to put an enclsure around the transformers, since this will definitely make the amp much more more esthetic and safe.

In this design, the PCB will be attached to the bottom of the top lid, such that intricate wiring becomes no longer an issue

Now, before starting to design a 2D metal sheet layout, one needs to decide what material/thickness to use. In my case, I will be working with 16 and 24 gauge steel. The 16 gauge steel is for the box lid (to make it stronger) and the 24 gauge steel is for everything else (to bend it easily and have it with a relatively light final weight). Steel is also easy and safe to weld (unlike in the case of aluminium)

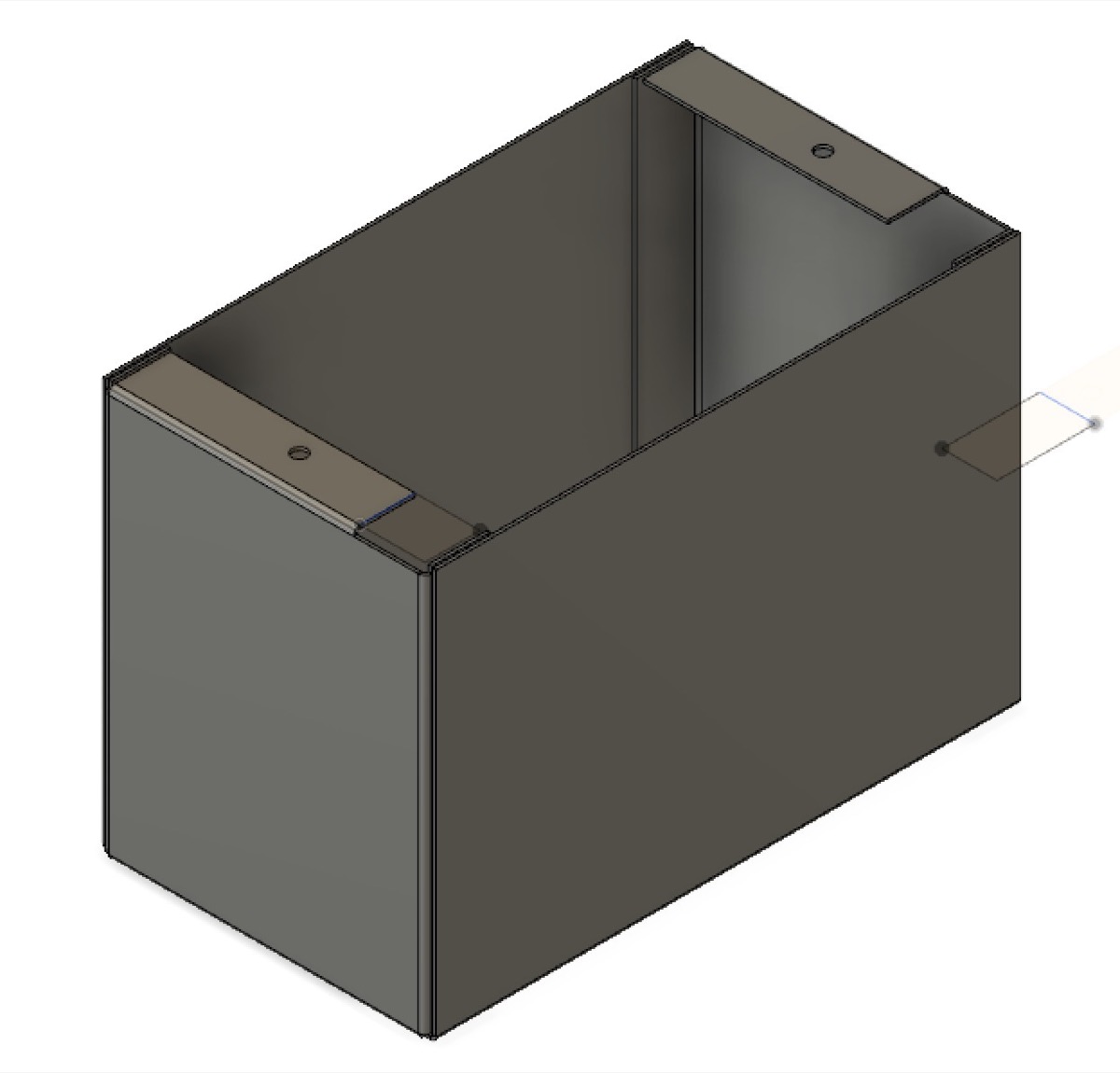

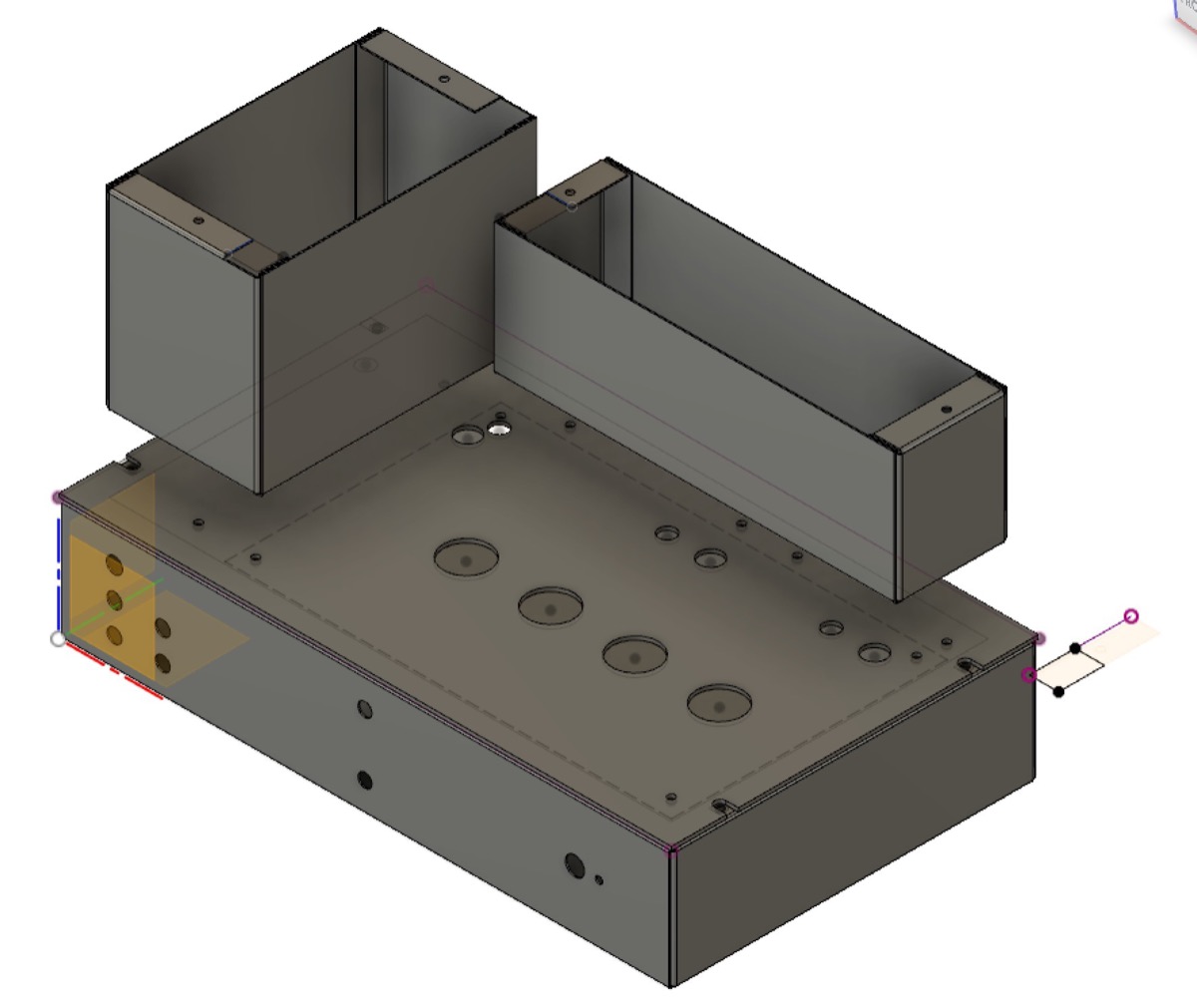

Transformer box enclosure

Transformer box enclosure

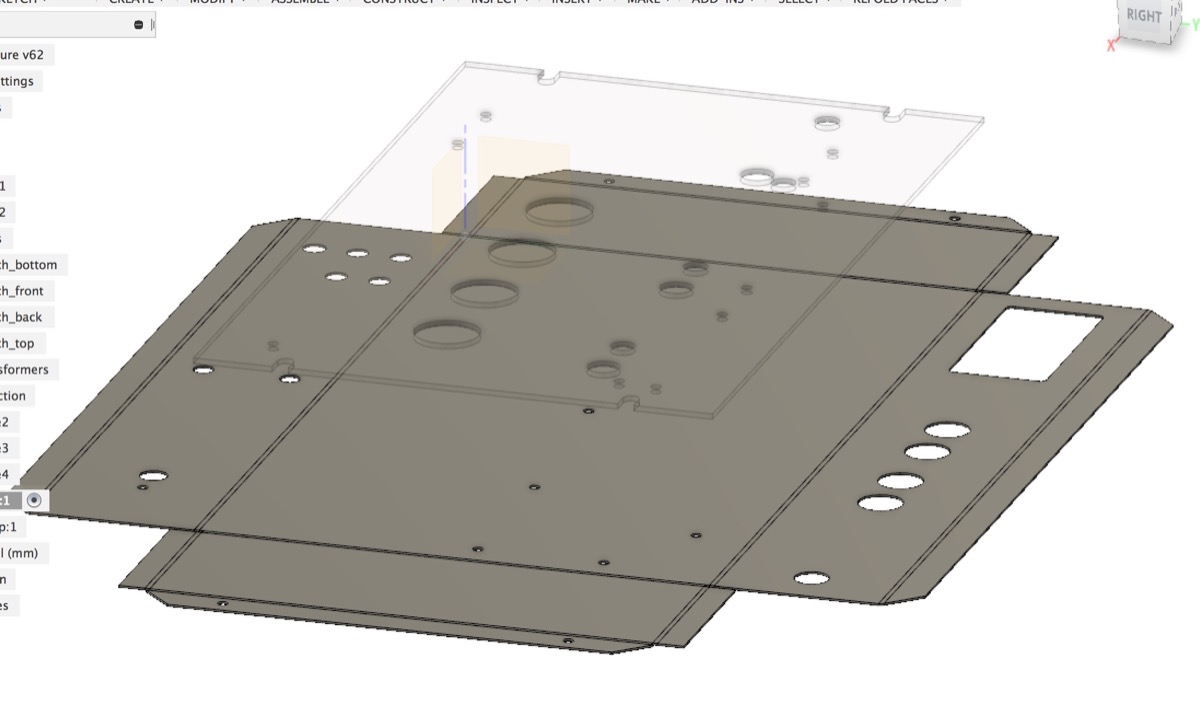

Transformer box enclosure unfolded

Transformer box enclosure unfolded

Amplifier enclosure

Amplifier enclosure

Amplifier enclosure unfolded

Amplifier enclosure unfolded

Complete set of enclosures (transofmer boxes are flipped)

Complete set of enclosures (transofmer boxes are flipped)

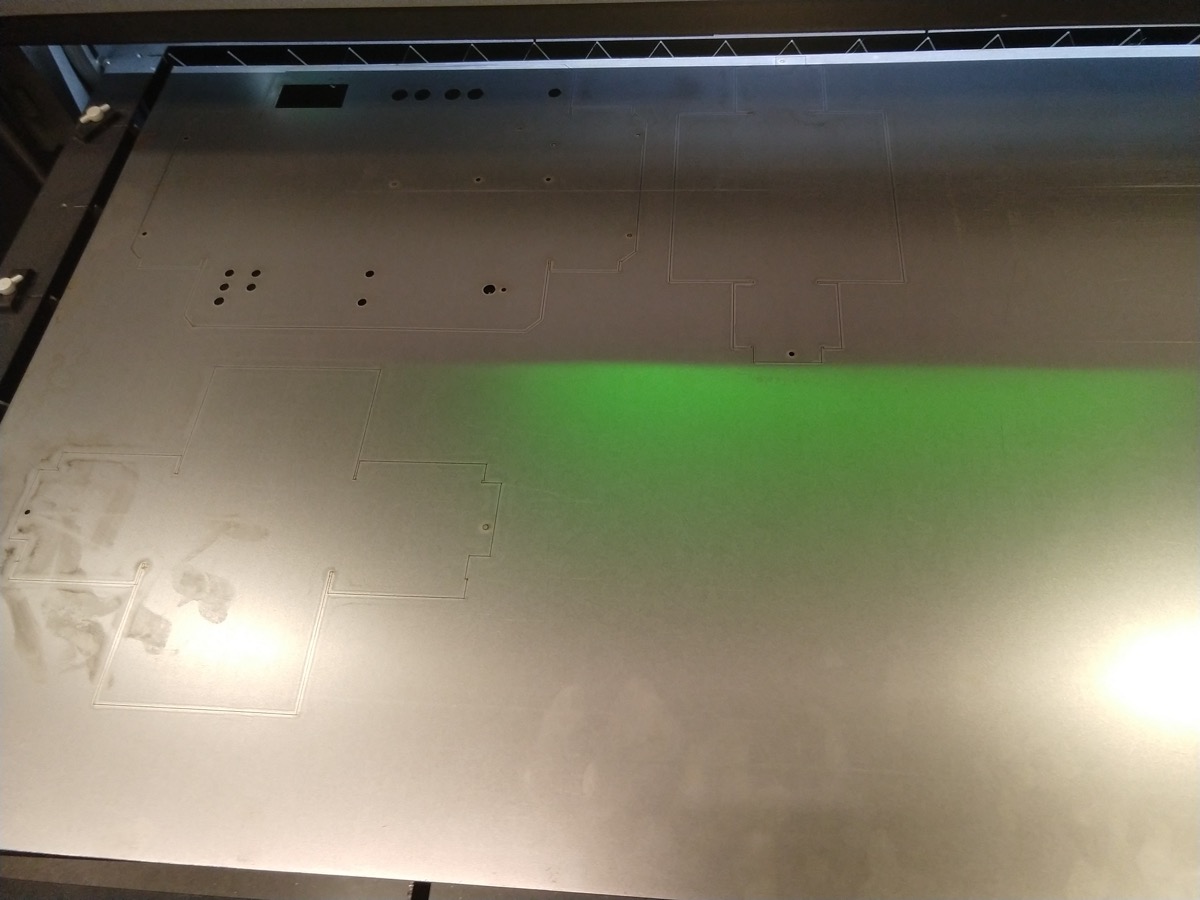

Laser-cutting the sheet of stainless steel with the FabLight

The sheet of steel after the laser-cutting

The sheet of steel after the laser-cutting

The start of the journey of manual bending

The start of the journey of manual bending

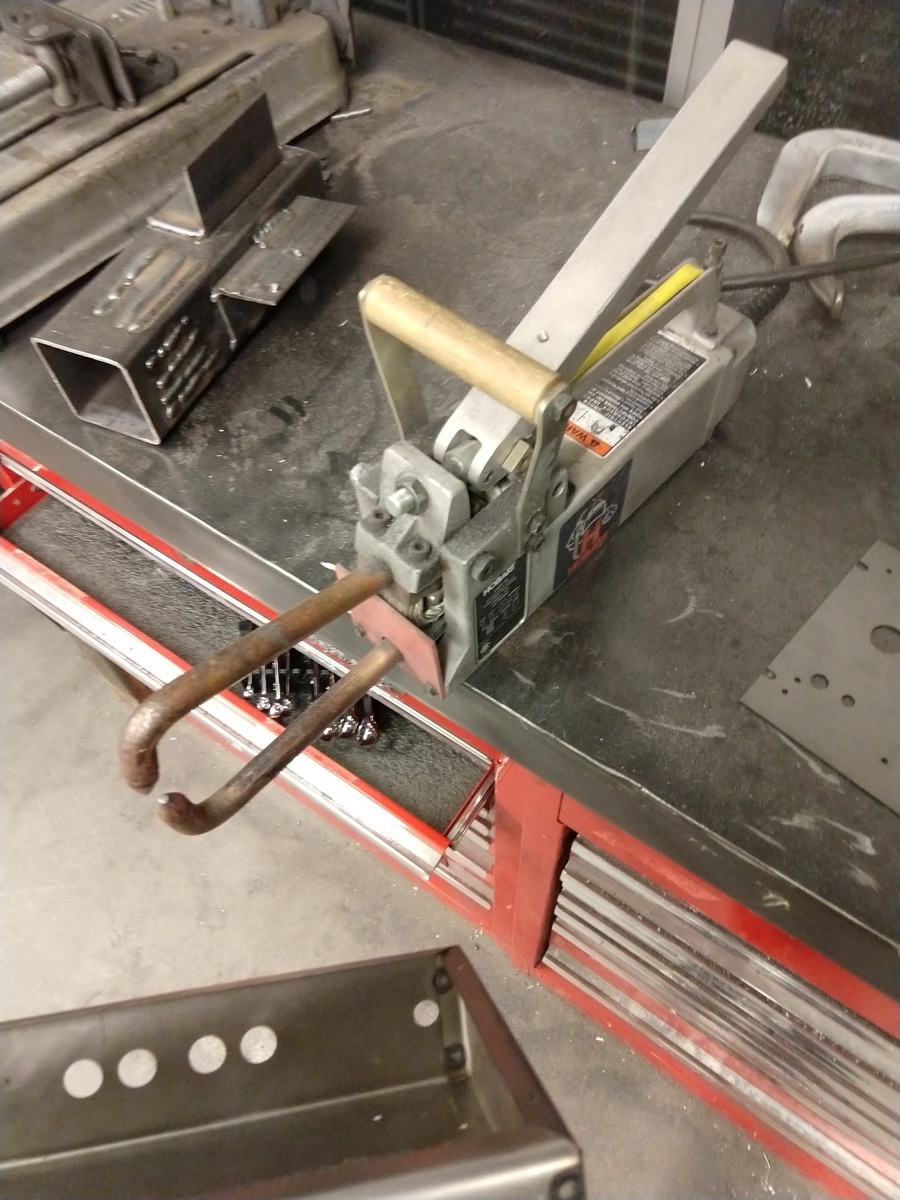

The tool for bending sheets of metal

The tool for bending sheets of metal

Spot welding tool

Spot welding tool

The milling, bending and welding are finished

Final enclosure outcome (front view)

Final enclosure outcome (rear view)