Amnahir: How to Make (Almost) Anything

Amnahir: MAS.863

This will be great!

About

For the eigth week, we had to mold and cast something. This was particularly exciting to me, as my project for 3.042 (the course 3 capstone) involves the casting and curing of diferent materials onto a glove. For this reason, I was excited to create a different mold and cast that. Sadly, I was not able to make something too complicated, as I had Bronchitis and could barely think/ couldn't leave my room for most of the week.

In the end, I decided to just make a ball, since I figured I could use it as a paperweight. In Fusion 360, I CADed the ball. It took a lot of tries, since I wanted to make the process as efficient as possible, so I wanted to ensure that I cut as little as possible. So I created a ball with a 20mm diameter. I then had the cylinder diameter 13mm connected to it, which seemed a little big, but I didn't realize until after I made it. I also ensured to add 4 mini circles on the edges of the square, to ensure that I could perfectly line up the sections. One side of the mold has the circle concave and the other convex.

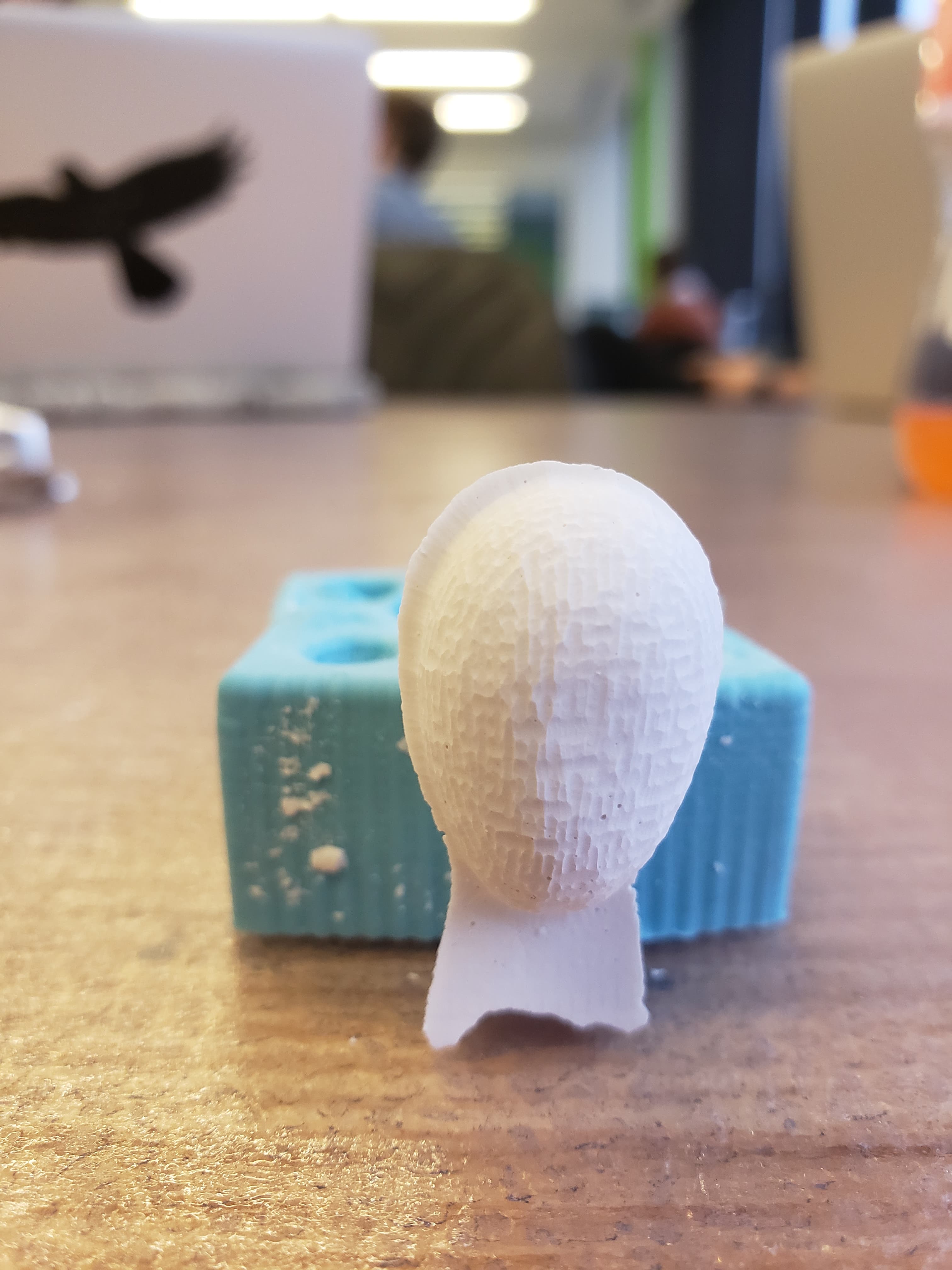

In the end, it appeared that I did not mix perfectly the oomoo in a ratio of 1:1, so after 1 hr it had not fully cured. However, I decided it seemed good enough, so I poured the hydrostone into the mold. Sadly, once I used the rubber bands, the oomoo deformed a lot, leading to the creation of a head looking structure as opposed to a sphere. I also know that it was not perfectly cured, as when I came back, both sides of the mold had cured to each other.

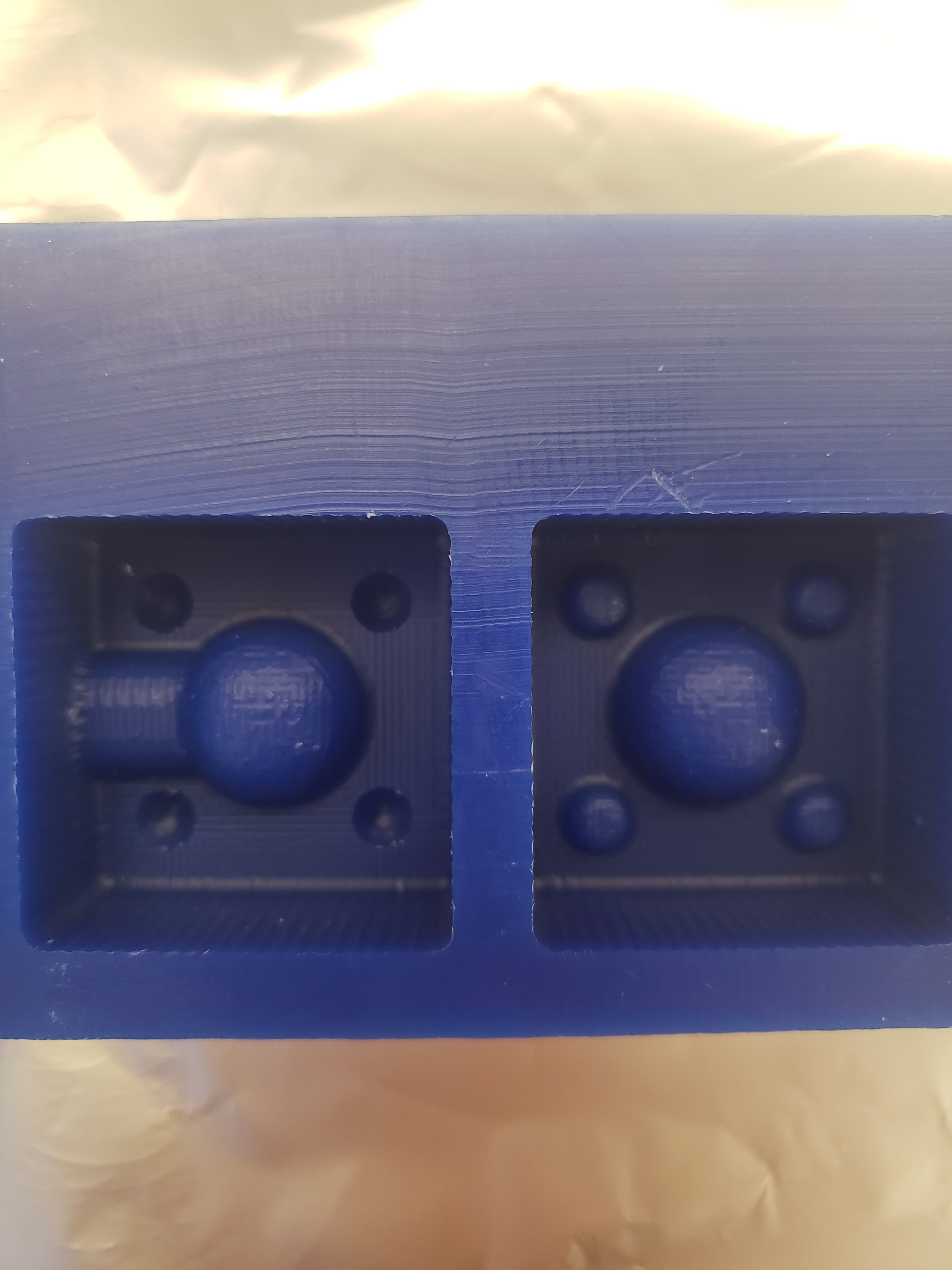

The Wax Mole

This is the milled wax, which shows the sphere that will be made.

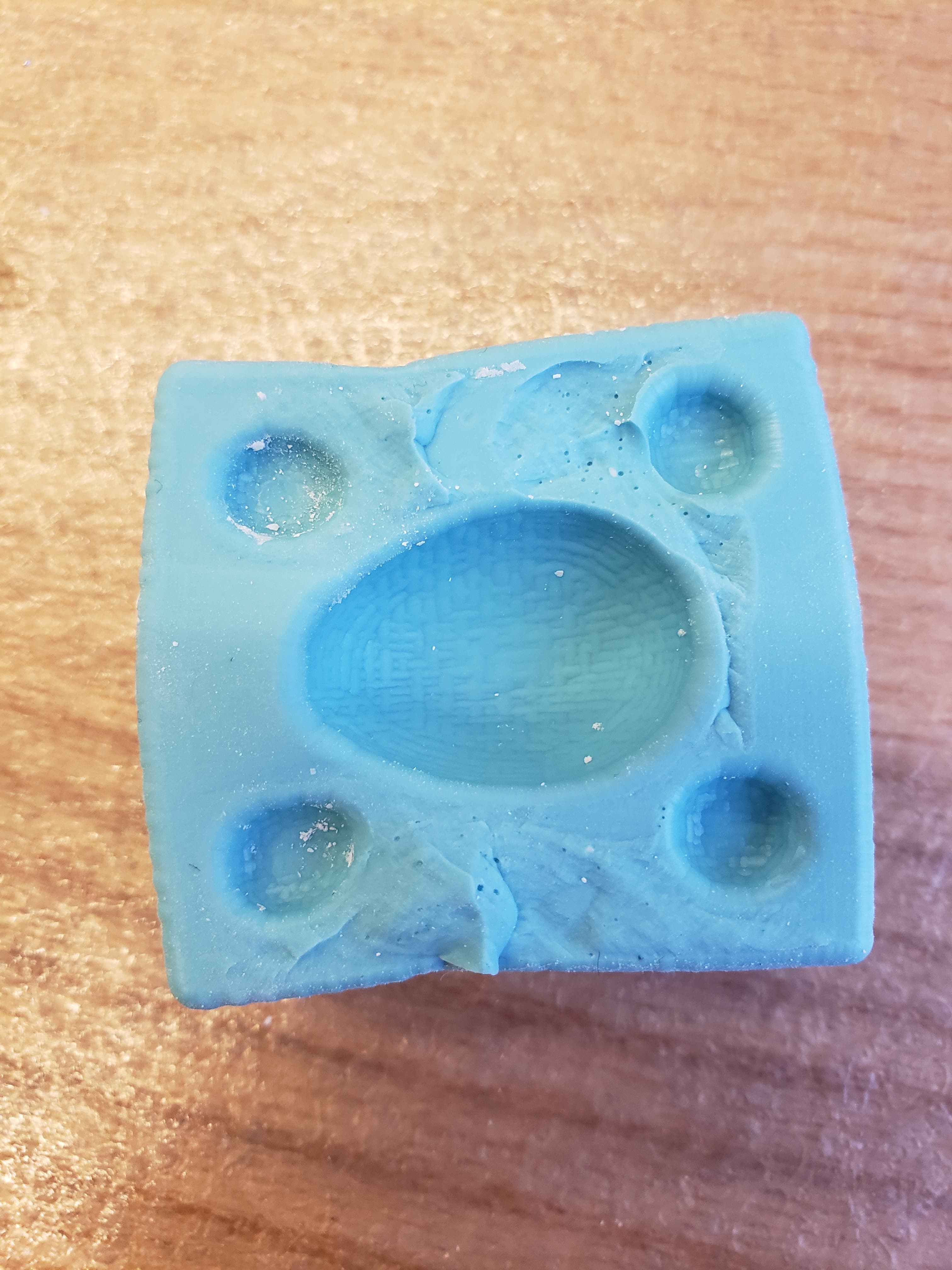

One half of the Mold

This shows the half of the mold after being used. It is slightly deformed from the rubber bands used.

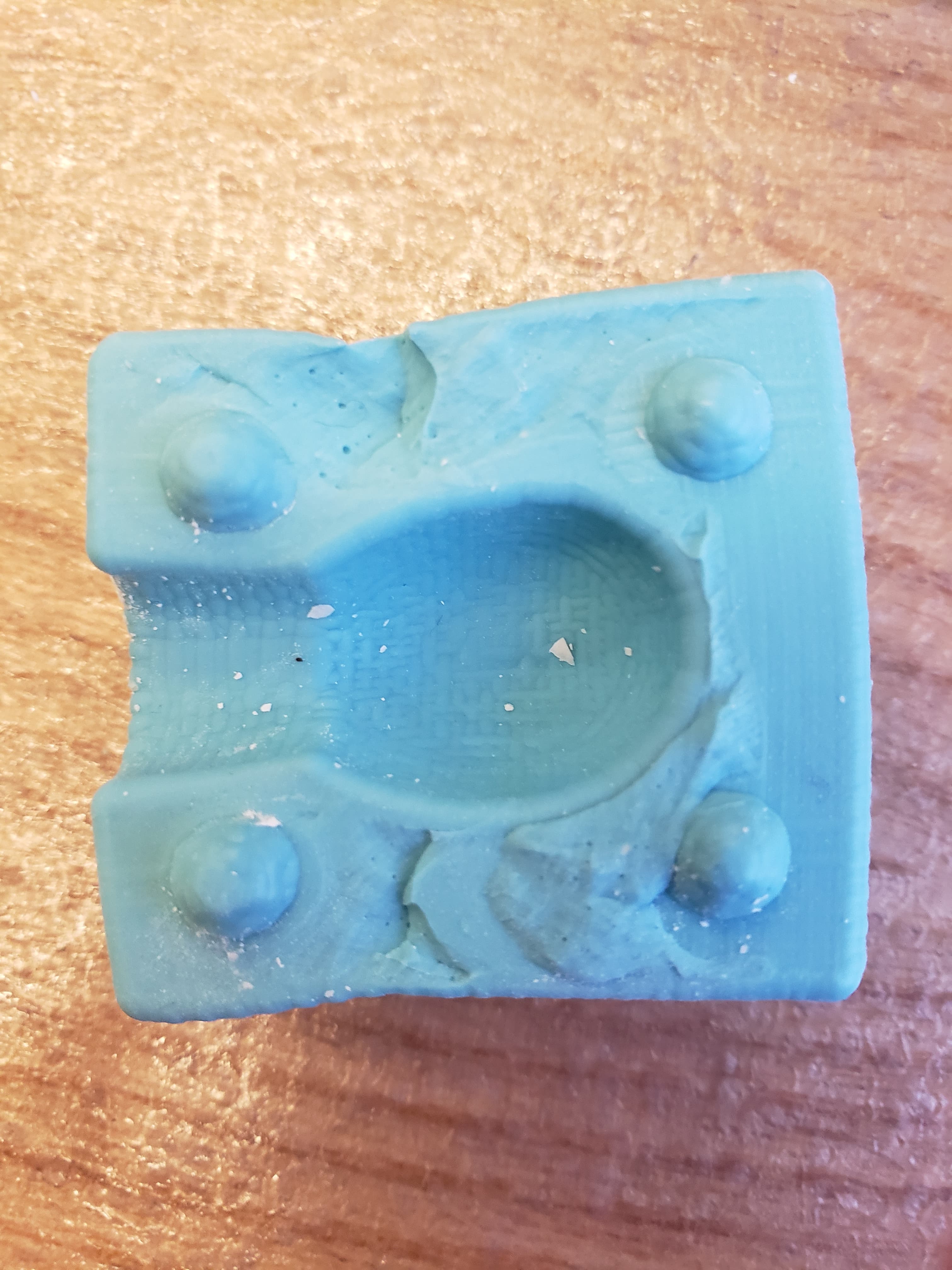

Second half of the Mold

This shows the half of the mold after being used. It is slightly deformed from the rubber bands used.

The Final Product

This shows the final product. It clearly is not a sphere from the deformation during the casting. However, I think it looks like a head!