Amnahir: How to Make (Almost) Anything

Amnahir: MAS.863

This will be great!

About

For the fifth week, we had to design our own circuit boards. We were given an initial board picture, which we were supposed to mimic. We then had to add a LED and a button. Since I had been using Fusion 360 for all of the CAD assignments, I decided to create the circuit board on Eagle. This took a lot of time as I was struggling to understand how to insert all of the downloads that were uploaded on the class website. After spending a couple hours struggling with everything, I managed to download all of the processes and add them to Eagle. So, I finally had access to all of the different components that I needed for the assignment.

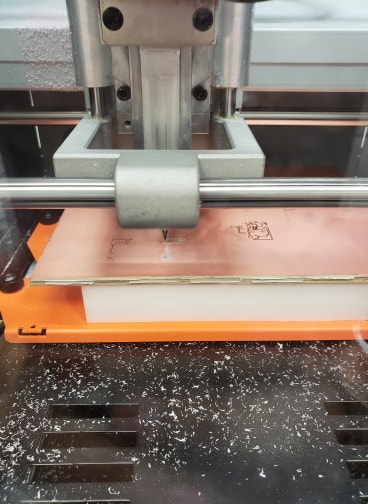

I used the mill and had to reset the images multiple times, as the dpi setting was off. I would export the image from Eagle at 1000 dpi. However, I would have to set the dpi on the mods to 2000 otherwise the board would be twice as large as required.

I used the mill and had to reset the images multiple times, as the dpi setting was off. I would export the image from Eagle at 1000 dpi. However, I would have to set the dpi on the mods to 2000 otherwise the board would be twice as large as required.

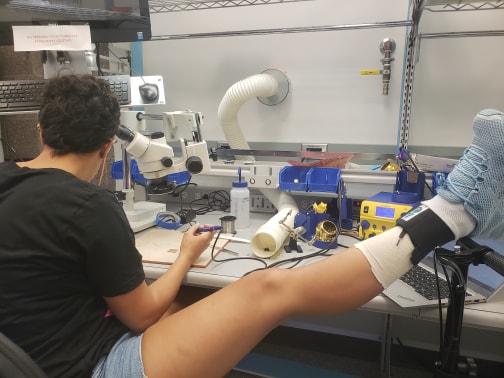

I also had to put off working on the board, since I injured my ankle on Thursday. Since I couldn't walk without a knee scooter and couldn't wear a shoe, I thought I wasn't allowed in lab. As I didn't heal in time, I ended up having to work while still injured. This involved trying to get around the tight spaces in the lab on a knee scooter, while also trying not too hit too many people or things. I also have to elevate my foot while I work, so I was forced to do this while soldering.

In order to test the piece, I used a multimeter and measured the resistance between different components and solder joints.

In order to test the piece, I used a multimeter and measured the resistance between different components and solder joints.

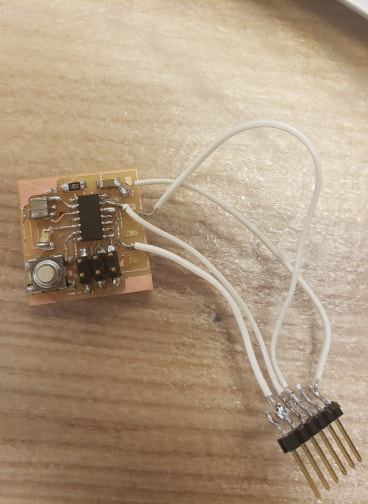

This was an incredibly tiring week, as the first board I made kept failing miserably. Through testing each solder joint separately, I ended up having to re-solder every single aspect. At one point, the FTDI component ripped off of the PCB with all of the copper pieces. Since the line for the mill was so long, I decided to keep working on this mill by using wires to connect the FTDI.

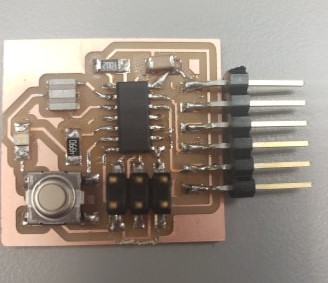

In the end, I was forced to mill another board. I made a couple changes to the board, which involved incorporating a resistor for the LED. I also separated some of the wires, so that it could mill better. Thankfully this one did not prove too difficult to work with. I was then able to create a good board, which was tested.

In the end, I was forced to mill another board. I made a couple changes to the board, which involved incorporating a resistor for the LED. I also separated some of the wires, so that it could mill better. Thankfully this one did not prove too difficult to work with. I was then able to create a good board, which was tested.